ABOUT US

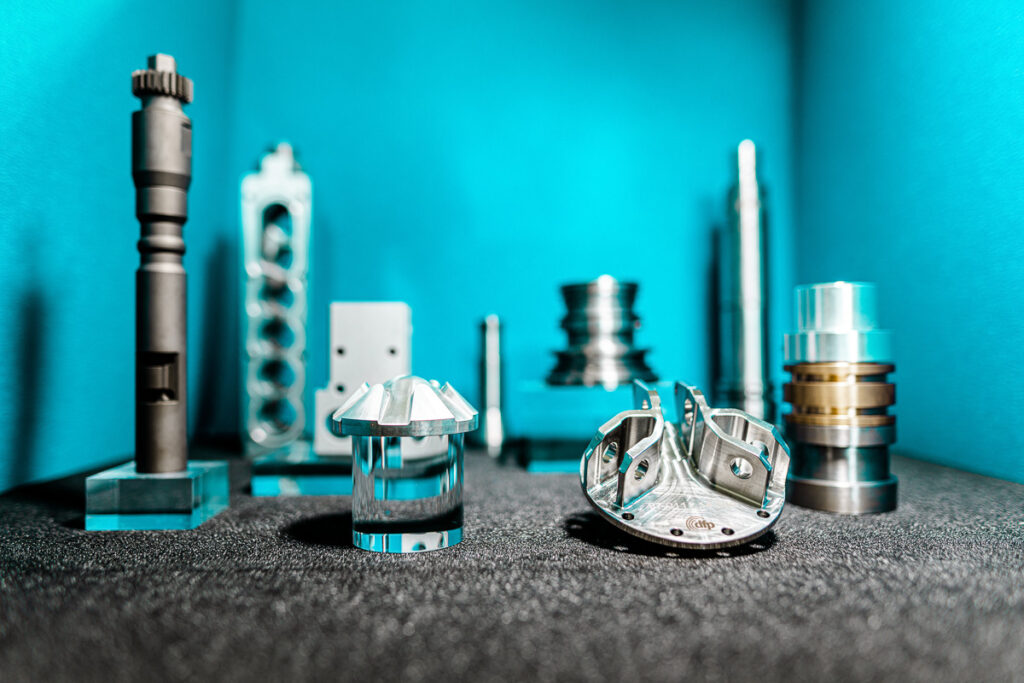

DFP Pott GmbH has been your expert and partner for the automated production of complex precision partssince 2007.

At Am Siesel in Plettenberg, your technological challenges are transformed into needs-based, user-oriented individual parts, (small) series and assemblies.

INDIVIDUAL REQUIREMENTS

SPECIALISTS IN DESIGN

As specialists in the machining of all metals, non-ferrous metals and plastics in the micrometre range, we manufacture precisely to your individual requirements – from individual parts to small series.

Our highly qualified employees, our efficient, innovative tool technology and high-precision clamping technology, as well as our automated 5-axis precision production and advanced hardware/software (incl. resource planning system) ensure that we can always meet the highest quality demands of a wide range of industries, such as medical and food processing technology, special engineering and plant construction or the automotive industry.

QUALITY THROUGH QUALIFICATION

FOR MAXIMUM CUSTOMER SATISFACTION

Our quality management system ensures that all requirements placed on us are met in full.

For this purpose, all processes – from the first contact to the delivery – are controlled accordingly and designed in the sense of customer satisfaction. The result: Our company is certified according to DIN EN ISO 9001:2015.

TO DO WELL IS BETTER THAN TO MEAN WELL.

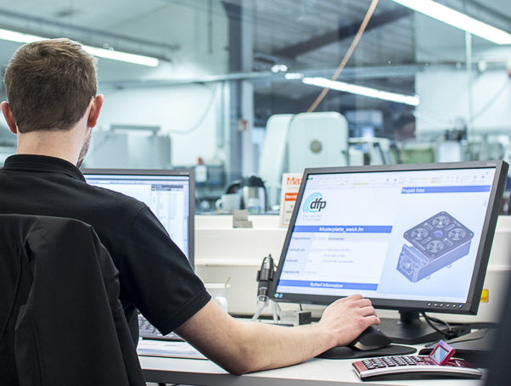

TRACEABILITY IS BEST

Our manufacturing process is fully interconnected. This allows us to measure all components continuously and monitor every step meticulously.

It enables us to ensure that all moulded parts are accurate to the hundredth of a millimetre, and we are also always able to correct any ambiguities immediately by means of highly precise traceability.

This is one of the measures of our Continuous Improvement Process (CIP), an integral part of our quality assurance.

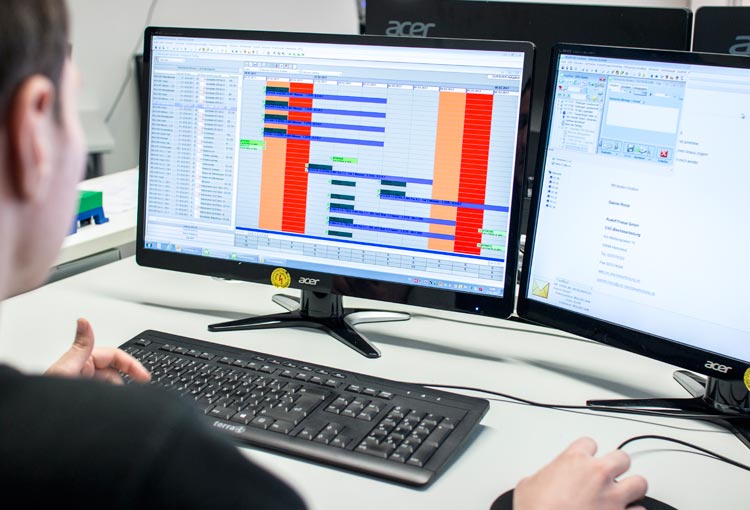

PAPERLESS DATA & INFORMATION FLOWS

SHORTER PRODUCTION TIME

With our consistent orientation towards the developments of Industry 4.0, we ensure that we are able to realise ever more complex shapes in ever shorter production times.

In doing so, we focus on optimising not only the communication between the machines themselves, but also between the machine and the operator.

RESOURCES & SUSTAINABILITY

100% CLEAN ELECTRICITY

For many years now, we have been practising active sustainability management, which is subject to constant optimisation and adaptation to the latest scientific knowledge and developments and covers virtually all areas of our company – from the procurement of raw materials to storage, from our production to disposal and logistics.

Our energy supply is also 100% secured by green electricity and we rely on environmentally friendly technologies. Likewise, we live up to our role as a future-oriented company and train the skilled workers of tomorrow through our qualified training opportunities.